This post may contain affiliate links. If you purchase something through the link, I may receive a small commission at no extra charge to you.

Let’s get real. I have put on Heat transfer vinyl on about 150 million projects (that might be a SLIGHT exaggeration…but only slight!) I love heat transfer so much! I have applied it to bags, shoes, wood signs, shirts, backpacks, pillows, blankets, towels–basically all the fun things. And I about 149,999,998 of those projects work out fine! BUT occasionally I have a nightmare of “WHY WON’T THIS HEAT TRANSFER VINYL STICK!!!”

So I thought I would troubleshoot the reasons in case you ever get stuck in a nonstick vinyl situation.

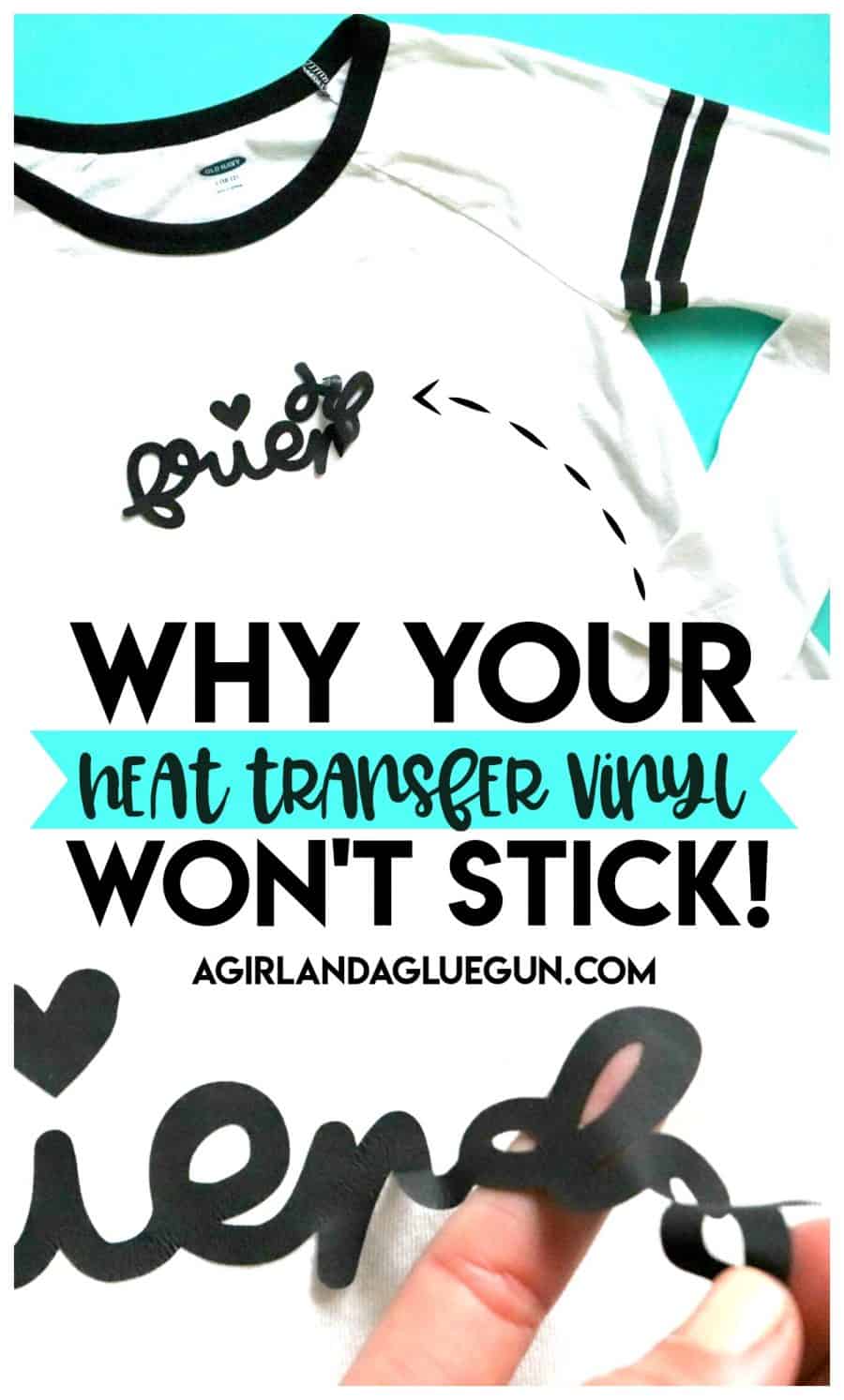

This shirt. insert the biggest eye roll. I made my daughter this custom shirt…on Christmas Eve. AND it worked just fine. She wore it and then mentioned that a few corners weren’t sticking (Which I just assumed was my bad for not pressing good enough in my holiday rush!) But I washed it. and you guys! The whole vinyl decal came off and was floating around my dryer.

Here is the mental checklist to see what could have happened:

WHY YOUR VINYL WON’T STICK

- Vinyl quality. Cheap-no brand vinyl can be real crappy! AND Vinyl does have a shelf life–so if it’s been hidden in your craft stash for a decade…it might be time to toss it.

- Heat and pressure. Each kind of vinyl comes with a recommended heat setting. Did you know you can ruin the adhesive by pressing too hot or too long (or both) And sometimes you don’t press long enough-Like it’s tacked down but you didn’t give it the full press so it will come up easily after some wear and tear. I usually press for 15 seconds at medium/high heat–not too long–not too short. and PRESS! Think about a heat press–it clamps down on it! So even if you are using an iron–put some pressure into it.

- Material. I’m way too lazy to prewash…but did you know that if you have a lot of fabric softener in your washer–it can create a coat on your item that is a barrier to prevent the heat transfer vinyl from adhering really well.

So this particular shirt was a conundrum. I HAD NEVER EVER HAD this happened to me before. I knew it wasn’t bad vinyl–I always buy from Expressions Vinyl. They have the best and I don’t have to worry about getting anything bad! PLUS I had just used this black vinyl on another sweatshirt just two days earlier–so I knew it wasn’t the cause. I also used the same temp settings as always. Plus this wasn’t just a corner peeling up.

So the final verdict is MATERIAL! This shirt is super soft (It’s from Old Navy) and even after washing it–I could not get any vinyl to stick! I think they must have added some kind of softness spray over it –great for wearing–bad for crafting!

I actually just ended up using a silk screen kit on it!

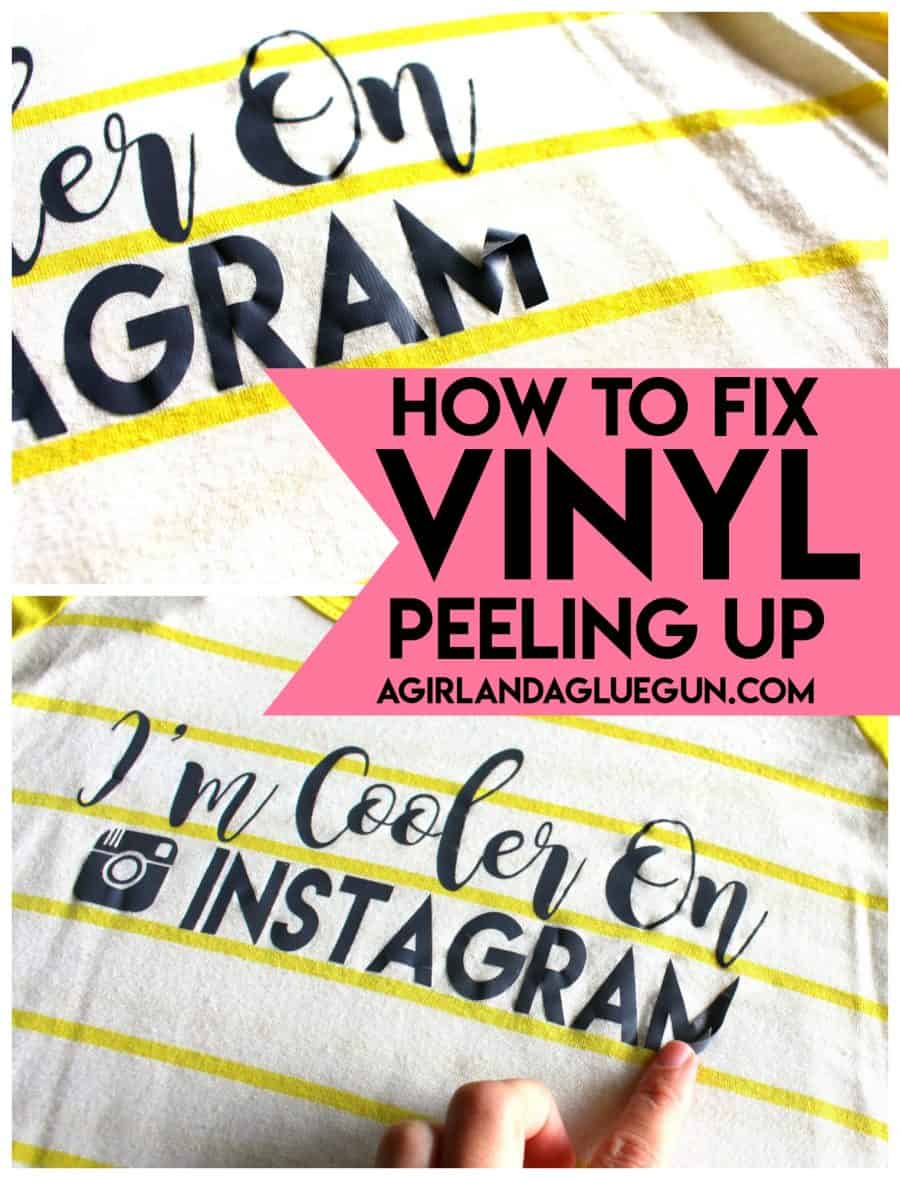

Now…something that happens quite regularly–is a corner of the vinyl peeling up! I actually get asked quite a bit about it!

Why the corners of your vinyl are peeling up.

The number one culprit is not pressing it. It’s always the corners–you press really good in the middle and really good and really good–but there is always one little spot that gets overlooked–Then after you wash–it peels up! (Usually only happens with an iron–which is what I use the majority of the time~) It’s actually a super easy fix–and I put a quick video on how to press it back down!

If you want more heat transfer vinyl posts–head here!

Angela says

I can’t get the vinyl to transfer to a project it won’t come off the transfer tape

Kimbo says

for adhesive vinyl or heat transfer? I’m assuming you mean adhesive vinyl. Some surfaces (like freshly stained wood) the vinyl won’t stick really well too. (you can spray it with a sealant to get a better grip) and sometimes the transfer tape is super sticky (I know cricut has a brand that is super sticky) You need to pull the transfer back on its self and go really slow. using your application tool or a credit card you can hold the vinyl pieces down as you work the transfer tape off! It’s slow going but works!